|

The C0 and C1 cameras share majority of features, like the used

sensors, USB interface, autoguider port, etc. At the first view, the

only difference is the size of camera body.

C0 camera But greater dimensions of the C1 models allowed adding of some

features, not available on the C0 cameras, like cooling fan and

mounting threaded holes.

C1 camera

| Feature |

C0 |

C1 |

| Dimensions |

50 × 50 × 40.4 mm |

57 × 57 × 46.4 mm |

| Weight |

115 g |

170 g |

| Cooling fan |

No |

Yes |

| Tripod and metric threads |

No |

Yes |

Comparing the C0 (left) and C1 (right) cameras C0 and C1 camera models are equipped with Sony IMX global

shutter CMOS detectors with 3.45 × 3.45 μm square pixels.

Individual models differ in resolution only.

All used sensors utilize global electronic shutter. This means

every pixel within the image is exposed in the same time, as opposed

to rolling shutter sensors, which exposes individual lines one after

another. There is no difference for long exposures of static objects,

but imaging of moving objects using short exposure time using rolling

shutter leads to image shape distortions.

Two lines of C1 cameras are available depending on the

available dynamic range (bit-depth of the digitized

pixels):

C1 cameras with Sony IMX sensors supporting 8- and 12-bit

digitization. Because every 12-bit pixel occupies two bytes

when transferred to host PC, 12-bit image download time is longer

compared to 8-bit image. Maximal FPS in 8-bit mode is then

significantly higher. C1 cameras with Sony IMX sensors supporting 12-bit

digitization only. As the 12-bit read mode is always used for

long-exposure applications (astronomical photography, scientific

research) either way, lower theoretical download time in 8-bit mode

brings no limitations for real-world scenarios. All other parameters

being same (sensor size, resolution, pixels size, noise, …), lower

price of these cameras may be then very attractive.

C1 camera models with 8- and 12-bit digitization:

| Model |

CMOS sensor |

Resolution |

Pixel size |

Image area |

| C0/C1-1500 |

IMX273 |

1456 × 1088 pixels |

3.45 × 3.45 μm |

5.02 × 3.75 mm |

| C0/C1-3000 |

IMX252 |

2064 × 1544 pixels |

3.45 × 3.45 μm |

7.12 × 5.33 mm |

| C0/C1-5000 |

IMX250 |

2464 × 2056 pixels |

3.45 × 3.45 μm |

8.50 × 7.09 mm |

| C0/C1-12000 |

IMX253 |

4112 × 3008 pixels |

3.45 × 3.45 μm |

14.19 × 10.38 mm |

C1 camera models with 12-bit digitization only:

| Model |

CMOS sensor |

Resolution |

Pixel size |

Image area |

| C0/C1-3000A |

IMX265 |

2064 × 1544 pixels |

3.45 × 3.45 μm |

7.12 × 5.33 mm |

| C0/C1-5000A |

IMX264 |

2464 × 2056 pixels |

3.45 × 3.45 μm |

8.50 × 7.09 mm |

| C0/C1-12000A |

IMX304 |

4112 × 3008 pixels |

3.45 × 3.45 μm |

14.19 × 10.38 mm |

The C0 and C1 cameras are designed to work in cooperation

with a host Personal Computer (PC). As opposite to digital still

cameras, which are operated independently on the computer, the

scientific cameras usually require computer for operation control,

image download, processing and storage etc. To operate the camera,

you need a computer which:

Is compatible with a PC standard and runs modern 32 or 64-bit

Windows operating system. Is compatible with a PC standard and runs 32 or 64-bit Linux

operating system. Support for x64 based Apple Macintosh computers is also

included.

C1 cameras are designed to be connected with the host PC through

USB 3.0 interface, operating at 5 Gbps. Cameras are also compatible

with USB 2.0 port to communicate with a host PC.

Alternatively, it is possible to use the Moravian Camera

Ethernet Adapter device. This device can connect up to four Cx

(with CMOS sensors) or Gx (with CCD sensors) cameras of any type and

offers 1 Gbps and 10/100 Mbps Ethernet interface for direct connection

to the host PC. Because the PC then uses TCP/IP protocol to

communicate with the cameras, it is possible to insert WiFi adapter or

other networking device to the communication path.

Hint: Please note that the USB standard allows usage of cable no

longer than approx. 5 meters and USB 3.0 cables are even shorter to

achieve very fast transfer speeds. On the other side, the TCP/IP

communication protocol used to connect the camera over the Ethernet

adapter is routable, so the distance between camera setup and the host

PC is virtually unlimited. The C0 and C1 cameras do not need an external power supply to

operate, they are powered through the USB connection from the host

PC.

Note the camera must be connected to some optical system (e.g. the

telescope) to capture images. The camera is capable of long exposures,

necessary to acquire the light from faint objects. If you plan to use

the camera with the telescope, make sure the whole telescope/mount

setup is capable to track the target object smoothly during long

exposures.

C0 and C1 Camera System

Components of the C0 and C1 Camera system

include:

C0 camera head with CS-mount adapter C1 camera head with CS-mount adapter C0 camera head with combined T-thread (M42×0.75) and

CS-mount adapter C1 camera head with combined T-thread (M42×0.75) and

CS-mount adapter C/CS-mount to 1.25” barrel adapter Short (10 mm) variant of

C/CS-mount to 1.25” barrel adapter, intended for usage with

OAG Off-Axis Guider adapter (OAG) for cooled C1+ and C2

cameras Extension tube with M48 × 0.75 thread and

55 mm back focal distance Extension tube with M42 × 0.75 thread and

55 mm back focal distance (standard

T-thread adapter) Adapter for Canon EOS bayonet lens Adapter for Nikon bayonet lens

C1 camera versions

The C1 cameras underwent several innovation cycles through its

lifetime. Versions 1 and 2 differ only internally and they are

indistinguishable from the user point of view. The 3rd

iteration of the C1 camera design allowed to make the camera head

7 mm thinner and 45 g lighter. Beside the smaller and lighter body,

all other features (used sensors, USB and autoguider interfaces,

download time, …) are the same.

Comparison of the C1 v3 (left) and v1/v2 (right) models

shows the difference in camera thickness Camera Electronics

CMOS camera electronics primary role, beside the sensor

initialization and some auxiliary functions, is to transfer data

from the CMOS detector to the host PC for storage and processing.

So, as opposite to CCD cameras, CMOS camera design cannot

influence number of important camera features, like the dynamic

range (bit-depth of the digitized pixels).

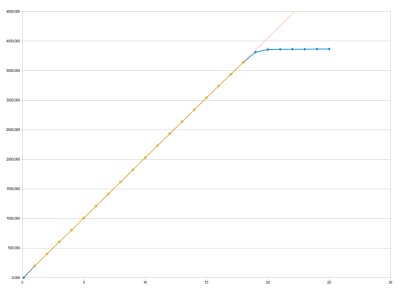

Sensor linearity

The sensors used in C1 cameras shows very good linearity in

response to light. This means the camera can be used also for

entry-level research projects, like for instance photometry or

brighter variable stars etc.

C1-3000 (IMX252) response to light Download speed

As already noted, there are two lines of C0 and C1

camera series, differing in the used sensor. The first

series offers four different read modes:

8-bit slow mode with ~132 MPx/s digitization

speed 12-bit slow mode with ~72 MPx/s digitization

speed 8-bit fast mode with ~263 MPx/s digitization

speed 12-bit fast mode with ~132 MPx/s

digitization speed

The “A” version of C0 and C1 cameras offers

only single read mode:

The digitization speeds mentioned above are valid for

USB 3.0 connection. Also please note the digitization speeds

do not necessarily lead to corresponding FPS, because every

image downloaded has to be processed and displayed, which also

consumes time. This time is negligible, if slow-scan camera

needs many seconds for image download, but in the case of fast

CMOS cameras, time for image processing in the PC (e.g.

calculation of image standard deviation etc.) can be longer

than image download itself.

Camera gain

Sensors used in C0 and C1 cameras offer programmable gain

from 0 to 24 dB, which translates to the output signal

multiplication from 1× to

15.9×. Gain can

be set with 0.1 dB step.

Conversion factors and read noise

Generally, many sensor characteristics depend on the used

gain. Hence, we provide two lists of parameters for both

minimal and maximal gain.

| Digitization resolution |

12-bit |

12-bit |

8-bit |

8-bit |

| Sensor gain |

0 dB |

24 dB |

0 dB |

24 dB |

| Full well capacity |

11000 e- |

1100 e- |

2600 e- |

1100 e- |

| Conversion factor |

2.8 e-/ADU |

0.3 e-/ADU |

10.0 e-/ADU |

4.4 e-/ADU |

| Read noise |

2.2 e- RMS |

2.0 e- RMS |

4.2 e- RMS |

9.7 e- RMS |

Exposure control

C0 and C1 cameras are capable of very short exposures. The

shortest exposure time is 125 μs (1/8000

of second). This is also the step, by which the exposure time

is expressed. So, the second shortest exposure is 250 μs etc.

Long exposure timing is controlled by the host PC and there

is no upper limit on exposure time. In reality the longest

exposures are limited by saturation of the sensor either by

incoming light or by dark current (see the following

sub-chapter).

Sensor Cooling

Dark current is an inherent feature of all silicone circuits.

It is called “dark”, because it is generated regardless if

the sensor is exposed to light or not. Dark current, injected into

individual pixels, appear in image as noise. The longer exposure,

the greater amount of noise is present in every image. As it is

generated by random movement of particles, it depends on the

temperature exponentially (this is why the noise generated by dark

current is also denoted “thermal noise”). Typically,

lowering the sensor temperature by 6 or 7 °C halves the dark current.

While neither C0 nor C1 cameras are equipped with active

thermo-electric (Peltier) cooling, the C1 models employ a small

fan, exchanging air inside the camera body. What is more, a small

heat sink is located directly on the sensor to remove as much heat

as possible (with the exception of C1-1500, which sensor is too

small to be equipped with a heat sink). So, the C1 sensor cannot

be cooled below the ambient temperature, but its temperature is

kept as close to environment as possible. Compared to closed

designs of C0 and other cameras, the sensor temperature in the C1

can be between 7 and 10°C lower and resulting dark current may be

less than a half.

Cooling air intake is on the right side of the camera

(left), while the output vents are on the opposite side

(right) The fan operation can be controlled from the software. SIPS

directly offers a slider controlling fan in the “Cooling”

tab of the imaging camera tool window. Camera drivers for other

software must rely on driver configuration dialog box to control

fan.

Without fan, the sensor in the C0-1500 camera reaches

temperature approx. 7°C above ambient (left), while the sensor

in the C1-1500 camera with running fan is kept very close the

ambient temperature Autoguider port

A lot of astronomical telescope mounts (especially the

mass-manufactured ones) are not precise enough to keep the star

images perfectly round during long exposures without small

corrections. Cooled astronomical cameras and digital SLR cameras

allow perfectly sharp and high-resolution images, so even a small

irregularity in mount tracking appears as star image deformations.

C0 and C1 cameras were designed especially with automatic mount

guiding on mind.

The C0 and C1 cameras were designed to operate without any

mechanically moving parts (with the exception of magnetically

levitating fan). Electronic shutter allows extremely short

exposures and also obtaining thousands of images in a short time,

which is necessary for quality guiding.

The C0 and C1 cameras work in connection with a host computer

(PC). Guiding corrections are not calculated in the camera itself,

it only sends acquired images to the PC. The software running on

the PC calculates the difference from required state and sends

appropriate corrections to the telescope mount. The plus side of

using a host PC CPU to process images is the fact, that current

PCs provide overwhelming computational power compared to any

embedded processor inside the guiding camera. Guiding algorithms

then can determine star position with sub-pixel precision, can

match multiple stars to calculate average difference, which limits

the effects of seeing, etc.

Calculated corrections can be sent back to mount using

PC-to-mount link. If the mount controller does not support

so-called “Pulse Guide” commands, it is possible to use

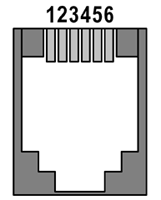

“Autoguider” port. It is enough to connect the C0 or C1

camera and the mount using standard 6-wire cable and guide the

mount through the camera.

The maximum sinking current of each pin of the C0 and C1 camera

is 400 mA. If the mount does not treat the autoguider port as

logical input only, but switches the guiding motors directly by

these signals, a relay box must be inserted between the camera and

the mount. The relay box ensures switching of currents required by

the mount.

Standard 6-pin Autoguider Port is located beside the

USB3 port on the top side of C1 (left) and C0 (right)

cameras The Autoguider port follows the de-facto standard introduced by

SBIG ST-4 autoguider. The pins have the following functions:

|

| 1 |

R.A. + (Right) |

| 2 |

Dec + (Up) |

| 3 |

Dec – (Down) |

| 4 |

R.A. – (Left) |

| 5 |

Common (Ground) |

| 6 |

Not connected |

|

Mechanical Specifications

C1 camera head is designed to be lightweight and compact to be

easily attached even to small telescopes or finders. Compact and

robust camera head measures only 57 × 57 × 48 mm not

including the lens adapter.

The head is CNC-machined from high-quality aluminum and black

anodized. The head itself contains USB-B 3.0 (device) connector

and standard 6-pin “autoguider” connector.

| Internal mechanical shutter |

No |

| Shortest exposure time |

125 μs |

| Longest exposure time |

Limited by chip saturation only |

| C0 head dimensions |

50 mm × 50 mm × 40.4 mm (including CS-mount adapter) |

| C1 head dimensions |

57 mm × 57 mm × 47.4 mm (including CS-mount adapter) |

| Back focal distance |

12.5 mm

for 1/32 UN thread (CS-mount compatible) |

| |

18.5 mm

for M42 × 0.75

thread (T-mount) |

| C0 head weight |

115 g |

| C1 head weight |

170 g |

Telescope/lens adapters

C0 and C1 cameras are supplied with two types of

telescope/lens adapters:

Adapter with 1/32 UN thread and

12.5 mm Back

Focal Distance (CS-mount). Adapter with M42 × 0.75 thread (T-thread)

and 18.5 mm

Back Focal Distance. This adapter also contains inner thread

1/32 UN with 12.5 mm BFD (CS-mount).

Comparison of C1 camera with CS- mount only adapter

(left) and C1 camera with combined T-thread (M42 × 0.75) and CS-mount

adapter (right) CS-mount it compatible with vast number of CCTV lenses. If

C-mount lens has to be used (with 17.5 mm Back Focal Distance), simple 5 mm thick adapter ring can be used.

Warning: If the C0 or C1 camera should be used with OAG for

cooled Cx cameras, short 10 mm C-to-1.25” barrel adapter has

to be used. This adapter, shipped with respective OAG, is

fully compatible with C0 and C1 camera. Note the C0 and

C1 cameras with M42 × 0.75 (T-thread) adapter

cannot be used with OAG, despite the short CS-to-1.25" barrel

adapter can be attached to it. The large-diameter M42 adapter

interferes with screws fixing the camera in the OAG guider

port. This is why C0 and C1 variant with CS-mount only adapter

are still supplied. C-to-1.25” barrel adapter, compatible with standard 1.25”

eyepieces, is included into camera package. So, the C0 or C1

camera can be easily mounted into virtually every astronomical

telescope instead of an eyepiece.

The T-mount interface (also known as T-thread adapter) is

defined by thread dimensions M42 × 0.75 as well as by

55 mm Back focal Distance.

T-thread adapter for C1 cameras does not comply to the second

parameter, its BFD is only 18.5 mm. The 55 mm

BFD is not required in all applications and keeping such

relatively large BFD would make the adapter quite bulky.

Still, an extension tube with male M42 × 0.75 thread is

available. This extension tube converts the C0 or C1 camera

BFD to 55 mm, required by

numerous focal-reducers, field-flatteners, coma-correctors and

other optical elements.

There are two variants of the 55 mm BFD extension tubes

available:

C1 camera (left), 55 mm BFD extension tube with M42 × 0.75 thread (center)

and with M48 × 0.75 thread

(right) Also, extension tubes with bayonet interfaces for

standard photographic lenses are available:

Hint: The extension tube outer diameter is exactly

2 inches

(50.8 mm), so it

can allow using of the C0 or C1 camera with any 2" focuser

instead of 2" eyepiece.

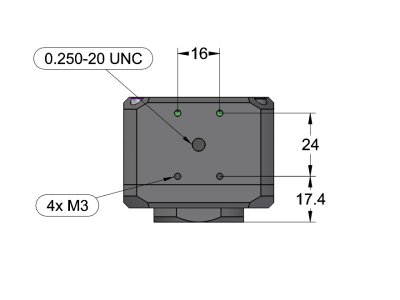

C1 camera with Canon EOS lens attached Tripod and metric threads

C1 camera bottom contains standard 0.25" (tripod)

thread and 4 metric M3 threaded holes If the C1 camera is not attached to the telescope focuser

through its telescope/lens adapter, it can be attached to

standard photographic tripod using 0.25” thread. Another

possibility is to use 4 metric M3 threaded holes, also located

on the bottom side of the camera head.

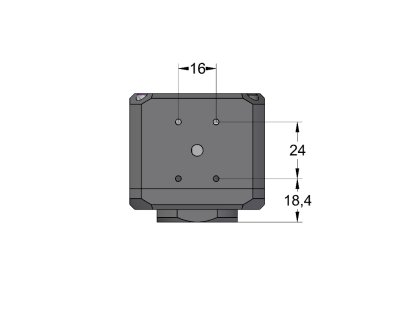

Position of the four M3 threaded holes on the

bottom of C1 v3 camera head The threaded hole pattern (thread diameter as well as hole

mutual distances) is the same for all versions of C1 cameras.

Only the holes were 1 mm further from the camera front side on

C1 cameras version 1 and 2.

Position of the four M3 threaded holes on the

bottom of C1 camera head C0 Camera Dimensions

C0 camera head with CS-mount adapter front view

dimensions (left) and side view dimensions and Back Focal

Distance (right) C0 camera head with M42 × 0.75 adapter front

view dimensions (left) and side view dimensions and Back

Focal Distance (right) C1 Camera Dimensions

C1 camera head with CS-mount adapter front view

dimensions (left) and C1 v3 side view dimensions and Back

Focal Distance (right) C1 camera head with M42 × 0.75 adapter front

view dimensions (left) and C1 v3 side view dimensions and

Back Focal Distance (right) Software support

Always use the latest versions of the system driver package for

both Windows and Linux system. Older versions of drivers may not

support new camera models (like C0) or latest versions or existing

series (like C1 version 3).

If the camera is controlled through the Moravian Camera

Ethernet Adapter, make sure the device firmware is updated to

the latest version available.

Also, always use the latest version of the SIPS software

package, older versions may not support latest cameras correctly.

If a driver for 3rd party software package is used

(e.g. ASCOM or INDI drivers), always update the driver to the

latest available version.

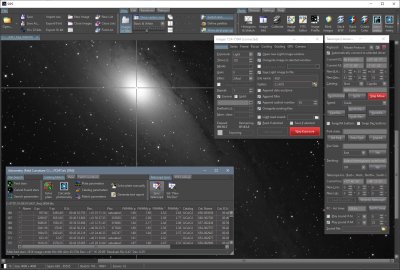

SIPS

Powerful SIPS (Scientific Image Processing System)

software, supplied with the camera, allows complete camera

control (exposures, cooling, filter selection etc.). Also

automatic sequences of images with different filters,

different binning etc. are supported. With full ASCOM standard

support, SIPS can be also used to control other observatory

equipment. Specifically the telescope mounts, but also other

devices (focusers, dome or roof controllers, GPS receivers

etc.).

SIPS also supports automatic guiding, including image

dithering. Both “autoguider” port hardware interface

(6-wire cable) and mount “Pulse-Guide API” guiding

methods are supported. For hi-quality mounts, capable to track

without the necessity to guide at last during one exposure,

inter-image guiding using the main camera only is

available.

SIPS controlling whole observatory (shown in

optional dark skin) But SIPS is capable to do much more than just camera and

observatory control. Many tools for image calibration, 16 and

32 bit FITS file handling, image

set processing (e.g. median combine), image transformation,

image export etc. are available.

SIPS handles FITS files, supports image calibration

and processing As the first “S” in the abbreviation SIPS means

Scientific, the software supports astrometric image reduction

as well as photometric processing of image series.

SIPS focuses to advanced astrometric and

photometric image reduction, but also provides some very

basic astro-photography processing SIPS software package is freely available for download from this www site. All functions

are thoroughly described in the SIPS User's Manual, installed

with every copy of the software.

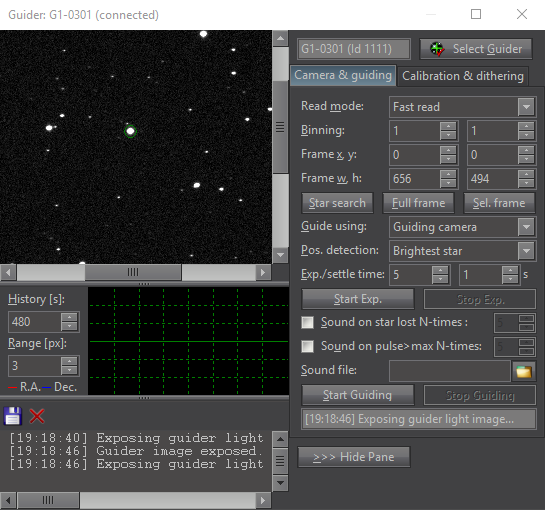

Automatic guiding

SIPS software package allows automatic guiding of the

astronomical telescope mounts using separate guiding

camera. Proper and reliable automatic guiding utilizing

the computational power of Personal Computer (e.g.

calculation of star centroid allows guiding with sub-pixel

precision) is not simple task. Guiding complexity

corresponds to number of parameters, which must be entered

(or automatically measured).

The SIPS “Guider” tool window The “Guiding” tool allows switching of

autoguiding on and off, starting of the automatic

calibration procedure and recalculation of autoguiding

parameters when the telescope changes declination without

the necessity of new calibration. Also swapping of the

German Equatorial mount no longer requires new autoguider

calibration. There is also a graph showing time history of

guide star offsets from reference position in both axes.

The length of graph history as well as the graph range can

be freely defined, so the graph can be adjusted according

to particular mount errors and periodic error period

length. Complete log of calibration procedure, detected

offsets, correction pulses etc. is also shown in this

tool. The log can by anytime saved to log file.

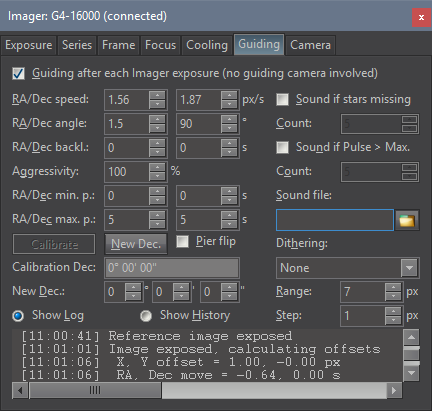

An alternative to classic autoguiding is the

inter-image guiding, designed for modern mounts, which are

precise enough to keep tracking with sub-pixel precision

through the single exposure, and irregularities only

appear on the multiple-exposure time-span. Inter-image

guiding then performs slight mount position fixes between

individual exposures of the main camera, which eliminates

“traveling” of the observed objects through the

detector area during observing session. This guiding

method uses main imaging camera, it does not use another

guiding camera and naturally does not need neither OAG nor

separate guiding telescope to feed the light into it.

Inter-image guiding controls in the

Guiding tab of the Imager Camera tool

window Advanced reconstruction of color information of

single-shot-color cameras

Color sensors have red, green and blue filters applied

directly on individual pixels (so-called Bayer mask).

Every pixel registers light of particular color only

(red, green or blue). But color image should contain all

three colors for every pixel. So it is necessary to

calculate missing information from values of neighboring

pixels.

There are many ways how to calculate missing color

values — from simple extending of

colors to neighboring pixels (this method leads to coarse

images with visible color errors) to methods based on

bi-linear or bi-cubic interpolation to even more advanced

multi-pass methods etc.

Bi-linear interpolation provides significantly better

results than simple extending of color information to

neighboring pixels and still it is fast enough. But if the

telescope/lens resolution is close to the size of

individual pixels, color artifacts appear close to fine

details, as demonstrated by the image below left.

The above raw image with colors calculated

using bi-linear interpolation (left) and the same raw

image, but now processed by the multi-pass de-mosaic

algorithm (right) Multi-pass algorithm is significantly slower compared

to single-pass bi-linear interpolation, but the resulting

image is much better, especially in fine details. This

method allows using of color camera resolution to its

limits.

SIPS offers choosing of color image interpolation

method in both “Image Transform” and “New Image

Transform” tools. For fast image previews or if the

smallest details are significantly bigger than is the

pixel size (be it due to seeing or resolution of the used

telescope/lens) the fast bi-linear interpolation is good

enough. But the best results can be achieved using

multi-pass method.

Drivers for 3rd party programs

Regularly updated Sofware Development Kit for Windows allows to

control all cameras from arbitrary applications, as well as

from Python scripts etc.

There are ASCOM standard drivers available together with

native drivers for some 3rd party programs (for

instance, TheSkyX, AstroArt, etc.). Visit the download page of this server to see a list of

all supported drivers.

Libraries and INDI standard drivers for 32-bit and 64-bit

Linux working on x86 and ARM processors are available as well. Also drivers for TheSkyX

running on macOS are supplied with all cameras.

First light images

The very first prototype of C1-3000 camera was used by

renowned astro-photographer Martin Myslivec. He used the Borg 77ED

refractor telescope on the EQ6 mount co capture several unguided

exposures. Despite we understand Martin is highly skilled and

experienced astro-photographer, the performance of C1 camera is

very good also for deep-sky imaging.

C1-3000 first light: M31 Great Andromeda galaxy (left),

M42 Great Orion nebula (center) and nebulosity around stars in

M45 Pleiades open cluster (right) The M31 Great Andromeda galaxy is a stack of 197

exposures 20 s long (approximately

1 hour and 5 minutes of total exposure time). No image processing

was performed beside individual frame calibration and slightly

non-linear stretching.

The M42 Great Orion nebula image was combined from two

sets of exposures (kind of HDR image processing). Faint

nebulosity, far from the image center, was acquired using 100

exposures 20 s long (approximately 33 minutes of total exposure

time). The very bright central part of the nebula was captured

with only 2 s long exposures (again 100 of them), which leads to

approximately 3 minutes of total exposure time. The very short

exposures allowed to perfectly capture the 4 central stars (called

Trapezium) without over-exposing them.

The image of M45 Pleiades is a combination of 218

exposures 20 s long (approximately 1 hour and 12 minutes of total

exposure time). Again, no image processing was performed, only the

calibration and slight non-linearly stretch was performed.

Sun in the Hα spectral line

Martin Myslivec used his global-shutter C1-5000 based

camera to acquire the Sun in the Hα line.

See what the C1 camera can achieve on the Sun.

|