|

G2CCD-0400 camera is equipped with ordinary SLR camera lens,

pointing to the microscope screen in the ultra high vacuum chamber.

Camera is attached to the microscope body using custom-made arm.

Exposure times vary within seconds, so it is not necessary to cool the

CCD chip below freezing pointthe KAF chip

generates approx. 1 electron per second per pixel at 0 deg.C.

G2CCD-0400 Camera on the Field Emission

Microscope Experiment results

The following images show the progress of experiment focused to

examination of growth and thermal stability of very thin palladium

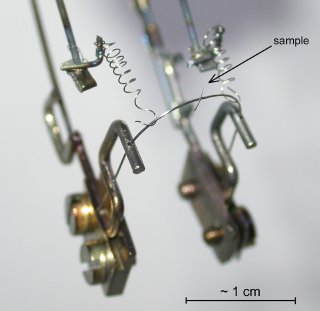

layer on the tungsten sample covered by tungsten oxide. The sample

is prepared from 0.2 mm thin tungsten wire etched to very sharp

tip.

The sample holder with tungsten tip prepared for

experiment The images below show field emission images of the tip during

experiment. Field of view covers 800 nm (0.000,8 mm) diametercamera

shows approx. 1.5 nm

per pixel. All images are displayed in false colors to enhance

subtle details.

The first figure shows the clean surface of the tungsten

monocrystal.

The second frame shows the sample surface after mild

oxidation.

Then a very thin layeronly

0.3 nmof palladium is evaporated on the tungsten oxide

surface cooled to 78 K.

The sample is then heated to approx. 350 and 500 K. After heating to 350 K (left image) palladium layer forms island

with cross shape influenced by tungsten oxide support. Additional

heating to 500 K (right image)

probably cause encapsulation of palladium by tungsten oxide (the

image is similar to bare oxidized tungsten before palladium

evaporation).

All images on this page are courtesy of Ing. Jan Plsek, PhD.,

J. Heyrovskı Institute of Physical Chemistry, Prague

|