|

C5 cameras are made in two versions:

Asymmetrical C5A variant look reveals the same time-proven

design school of the C3 and C4 series in both outer shape and internal

construction. The front cross-section of the C5A cameras is the same

as the C3 and C4 series, although the used sensors are much larger. C5

head thickness corresponds to the thickness of the Enhanced Cooling

versions of the earlier models.

Asymmetrical models also employ mechanical shutter, allowing to

capture dark or bias frames without a necessity to cover the telescope

aperture.

Symmetrical C5S variant main purpose is not to exceed the

central obstruction of reflecting telescopes with the camera located

in the primary focus. The asymmetrical variant typically overhangs the

central obstruction of smaller telescopes (with ~0.4 m primary mirror

diameter), despite the central obstruction of wide-field telescope is

rather big.

Due to mechanical constrains, the symmetrical model lacks the

mechanical shutter.

| Feature |

Asymmetrical C5A |

Symmetrical C5S |

| 100 and 150 MPx

sensors |

Yes |

Yes |

| Compatibility with filter wheels |

Yes |

Yes |

| M68 and M85 tiltable adapters |

Yes |

Yes |

| Mechanical shutter |

Yes |

No |

| Optional GPS receiver |

Yes |

Yes |

| Hardware trigger input |

No |

Yes |

Asymmetrical and symmetrical model comparison Compared to C3 and C4 cameras, both C5A and C5S series feature

completely redesigned air cooling — more

powerful and also quieter than even the EC variants of the C3 and C4.

Also, the supplied AC/DC brick power adapter is more powerful and

employs more robust power plug.

Usage of large sensors required completely new design of the

telescope interface and the C5 series offers M68 × 1 threaded adapter only on the smaller

100 MPx C5 variant. Large 150 MPx version of the C5 standardizes on the

M85 × 1 thread on the tiltable adapter.

Like in the case of the C4 series, the internal filter wheel is not an

option, external filter wheels are necessary and the C5 camera are

equipped to control new EFW-5XL series of filter wheels. Huge sensors

require huge 65 × 65 mm square filters and EFW-5XL-5 is designed for

five such filters. The EFW-5XL-7 filter wheels for seven smaller

50 × 50 mm

square filters are available for 100 MPx

C5 variant with smaller sensor.

Rich software and driver support allow usage of C5 camera without

necessity to invest into any 3rd party software package thanks to

included free SIPS software package. However, ASCOM (for Windows) and

INDI (for Linux) drivers and Linux driver libraries are shipped with

the camera, provide the way to integrate C5 camera with broad variety

of camera control programs.

The C5 cameras are designed to work in cooperation with a

host Personal Computer (PC). As opposite to digital still cameras,

which are operated independently on the computer, the scientific

cooled cameras usually require computer for operation control, image

download, processing and storage etc. To operate the camera, you

need a computer which:

Is compatible with a PC standard and runs modern 32 or 64-bit

Windows operating system. Is an x86 or ARM based computer and runs 32 or 64-bit Linux

operating system. Support for x64 based Apple Macintosh computers is also

included.

C5 cameras are designed to be attached to host PC through very fast

USB 3.0 port. While the C5 cameras remain compatible with older (and

slower) USB 2.0 interface, image download time is significantly

longer.

Alternatively, it is possible to use the Moravian Camera

Ethernet Adapter device. This device can connect up to four Cx

(and CCD based Gx) cameras of any type (not only C5, but also C1, C2,

C3 and C4) and offers 1 Gbps and 10/100 Mbps Ethernet interface for

direct connection to the host PC. Because the PC then uses TCP/IP

protocol to communicate with the cameras, it is possible to insert

WiFi adapter or other networking device to the communication path.

Hint: Please note that the USB standard allows usage of cable no

longer than approx. 5 meters and USB 3.0 cables are even shorter to

achieve very fast transfer speeds. On the other side, the TCP/IP

communication protocol used to connect the camera over the Ethernet

adapter is routable, so the distance between camera setup and the host

PC is virtually unlimited. Download speed is naturally significantly slower when camera is

attached over Ethernet adapter, especially when compared with direct

USB 3 connection.

The camera must be connected to some optical system (e.g. the

telescope) to capture images. As the C5 cameras offer really large

sensors with 67 mm (150 MPx version) and 55 mm

(100 MPx version) diagonals, optical

system must be capable to cover such large field of view. The camera

is designed for long exposures, necessary to acquire the light from

faint objects. If you plan to use the camera with the telescope, make

sure the whole telescope/mount setup is capable to track the target

object smoothly during long exposures.

C5 Camera Overview

C5 camera head is designed to be used with or without external

filter wheel. The EFW-5XL external filter wheel with 50 × 50 mm filters is

suitable for C5A-100M camera only, large sensor C5A-150M model

needs EFW-5XL external filter wheel, designed for 65 × 65 mm

filters.

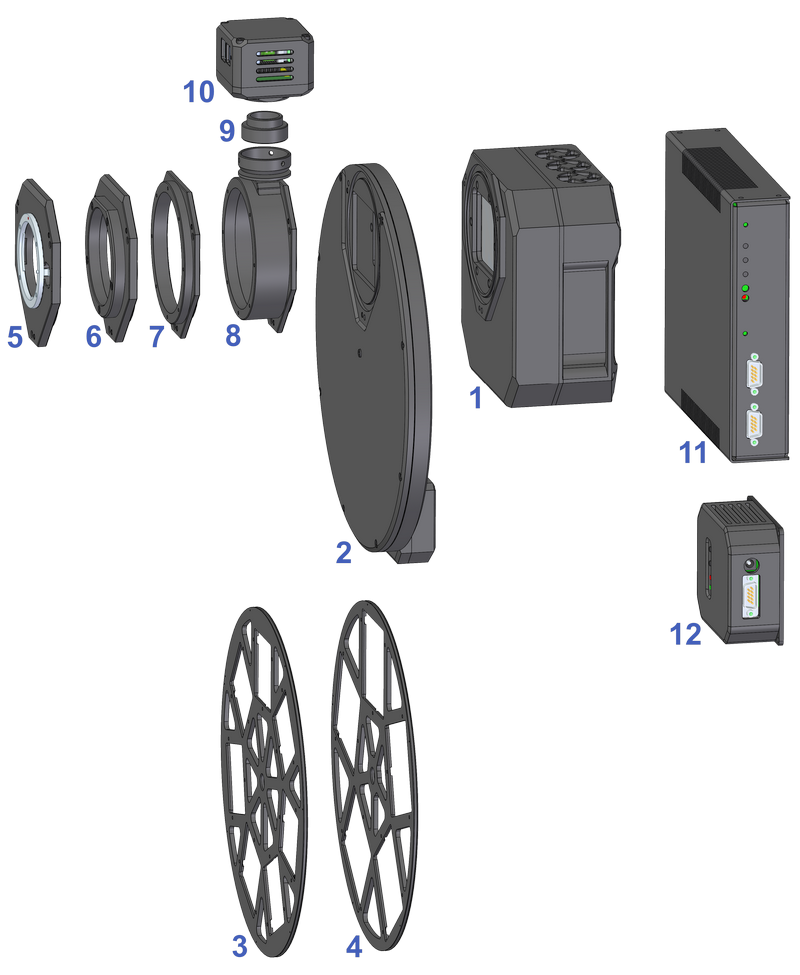

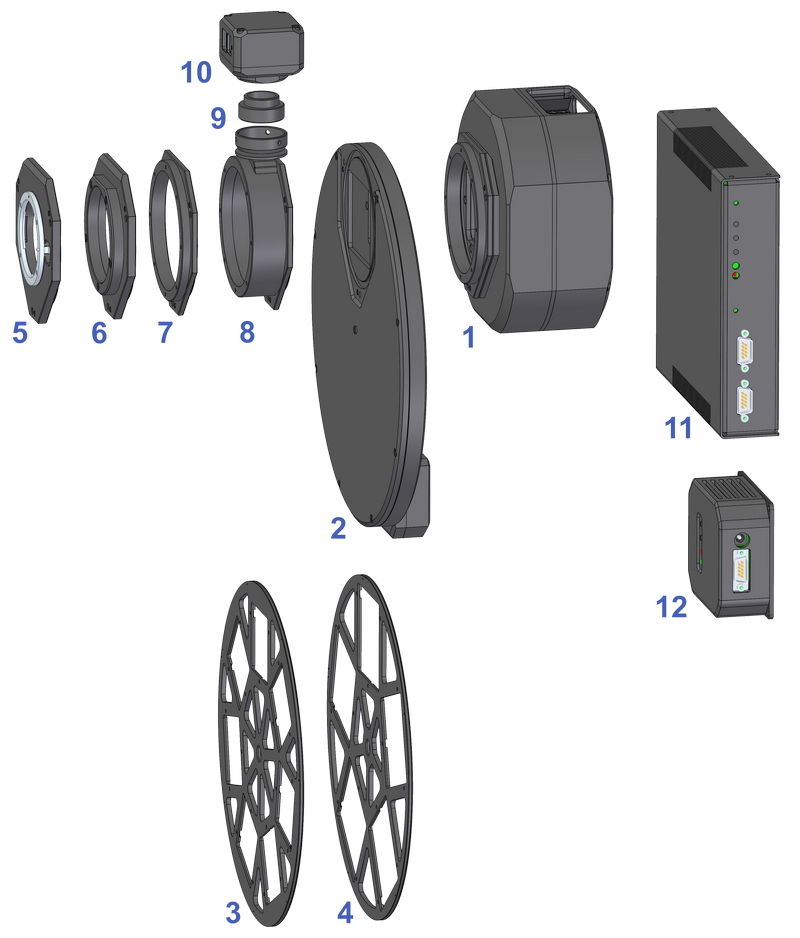

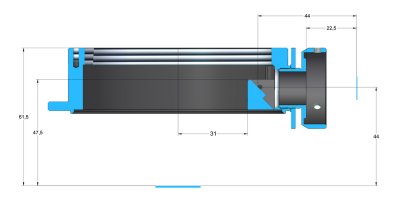

Schematic diagram of C5A camera system

Schematic diagram of C5S camera system Components of C5 Camera system include:

C5A or C5S camera head External Filter Wheel “XL” size 7-positions filter wheel for “XL” housing for

50 × 50 mm square filters 5-positions filter wheel for “XL” housing for

65 × 65 mm square filters Canon EOS bayonet adapter for the “XL” size

External Filter Wheel with 44 mm

BFD M68 × 1 threaded adapter,

BFD is 35 mm when

mounted directly on camera head and

47.5 mm when

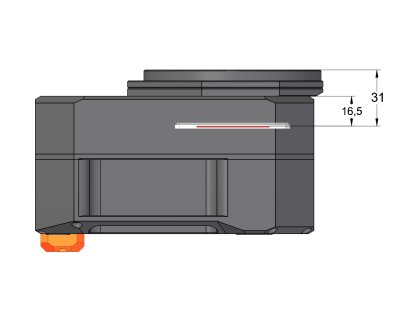

mounted on EFW M85 × 1 threaded adapter,

BFD is 31 mm when

mounted directly on camera head and

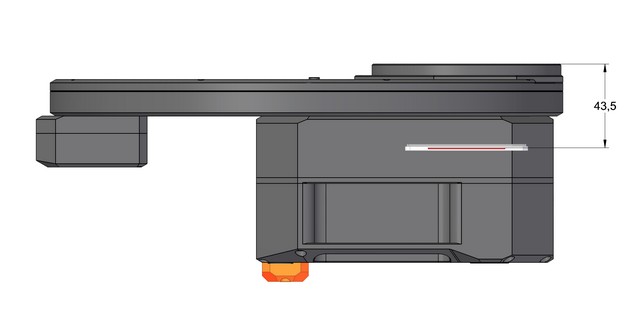

43.5 mm when

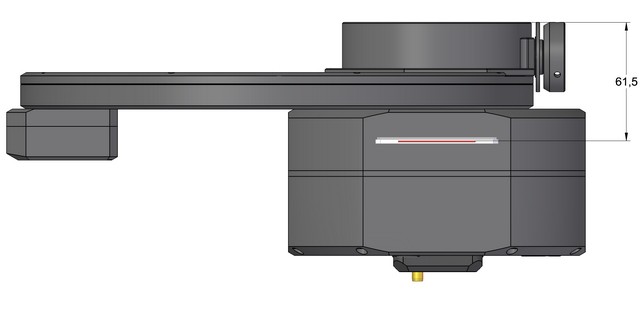

mounted on EFW C5-OAG (Off-Axis Guider Adapter) with M85 × 1 thread for the “XL” size External

Filter Wheel with 61.5 mm BFD 10 mm long CS-to-1.25"

adapter, used to attach CS-mount (C-thread,

12.5 mm BFD)

compatible guider cameras to the OAG C1 or C0 guider camera Moravian Camera Ethernet Adapter (x86 CPU) Moravian Camera Ethernet Adapter (ARM

CPU)

CMOS Sensor and Camera Electronics

Both C5A and C5S cameras are equipped with Sony IMX rolling

shutter back-illuminated CMOS detectors with

3.76 × 3.76 μm square pixels. Despite the relatively small pixel

size, the full-well capacity over 50 ke- rivals the full-well

capacity of competing CMOS sensors with much greater pixels and

even exceeds the full-well capacity od CCD sensors with comparable

pixel size.

The used Sony sensors are equipped with 16-bit ADCs (Analog to

Digital Converters). 16-bit digitization ensures enough resolution

to completely cover the sensor exceptional dynamic range.

C5 camera models include:

| Model |

C5A/C5S-100M |

C5A/C5S-150M |

| CMOS sensor |

IMX461 |

IMX411 |

| Color mask |

None |

None |

| Resolution |

11664 × 8750 |

14208 × 10656 |

| Pixel size |

3.76 × 3.76 μm |

3.76 × 3.76 μm |

| Sensor size |

43.86 × 32.90 mm |

53.42 × 40.07 mm |

Camera Electronics

CMOS camera electronics primary role, beside the sensor

initialization and some auxiliary functions, is to transfer

data from the CMOS detector to the host PC for storage and

processing. So, as opposite to CCD cameras, CMOS camera design

cannot influence number of important camera features, like the

dynamic range (bit-depth of the digitized pixels).

Sensor linearity

The sensors used in C5 cameras show very good linearity in

response to light. This means the camera can be used for

advanced research projects, like the photometry of variable

stars and transiting exoplanets etc.

Download speed

C5 cameras are equipped with on-board RAM, capable to hold

several full-resolution frames. Downloading of the image to

the host computer thus does not influence image digitization

process, as the download only transfers already digitized

images from camera memory.

Time needed to digitize and download single full frame

depends on USB connection type.

| Model |

C5A/C5S-100M |

C5A/C5S-150M |

| Full-frame, USB 3.0 (5 Gbps) |

0.66 s |

0.95 s |

| Full-frame, USB 2.0 (480 Mbps) |

5.57 s |

6.80 s |

If only a sub-frame is read, time needed to digitize and

download image is naturally lower. However, the download time

is not cut proportionally to number of pixels thanks to some

fixed overhead time, independent on the sub-frame

dimensions.

| Model |

C5A/C5S-100M |

C5A/C5S-150M |

| 1024 × 1024

sub-frame, USB 3.0 (5 Gbps) |

0.05 s |

0.05 s |

| 1024 × 1024

sub-frame, USB 2.0 (480 Mbps) |

0.07 s |

0.07 s |

Warning: The driver is sometimes forced to read bigger

portions of the sensor than the user defined because of a

sub-frame position and dimension limitations imposed by the

sensor hardware. Sometimes it is even necessary to read the

whole sensor. Hint: It is recommended to click the Adjust Frame

button in the Frame tab of the SIPS camera control

tool. The selected frame dimensions are then adjusted

according to sensor limitations. Adjusted frame is then read

from the sensor, without a necessity to read a bigger portions

or even whole sensor and crop image in firmware. C5 camera electronics supports in-camera 2 × 2 binning. If this binning mode is used,

download speed increases because of less amount of data read

from camera.

| Model |

C5A/C5S-100M |

C5A/C5S-150M |

| Full-frame 2 × 2 HW

binning, USB 3.0 (5 Gbps) |

0.43 s |

0.60 s |

| Full-frame 2 × 2 HW

binning, USB 2.0 (480 Mbps) |

1.15 s |

1.71 s |

Download speed when using the Moravian Camera Ethernet

Adapter depends if the 100 Mbps or 1 Gbps Ethernet is used, if

USB 2 or USB 3 is used to connect camera to Ethernet Adapter

device, but also depends on the particular network utilization

etc. When the camera is connected to the Ethernet Adapter

using USB 3 and 1 Gbps Ethernet is directly connected to the

host PC, download time of the C5-100M full frame is approx.

4 s and the

C5-150M needs approx. 6 s.

Camera gain

Sensors used in C5 cameras offer programmable gain from 0

to 36 dB, which translates to the output signal multiplication

from 1× to 63×.

Camera driver accepts gain as a number in the range 0 to

4030, which corresponds directly to sensor register value.

This number does not represent gain in dB nor it is an exact

gain multiply. However, the driver offers a function, which

transforms the gain numerical value to gain expressed in dB as

well as multiply. Some selected values are shown in the

table:

| Gain number |

Gain in dB |

Gain multiply |

| 0 |

0.00 |

1.00× |

| 1000 |

2.34 |

1.32× |

| 2000 |

5.82 |

1.95× |

| 3000 |

11.46 |

3.74× |

| 4000 |

32.69 |

43.11× |

| 4030 |

35.99 |

63.00× |

Conversion factors and read noise

Generally, many sensor characteristics depend on the used

gain. Also, the used sensors employ two conversion paths. One

path offers very low read noise, but cannot utilize full

sensor dynamic range. Another conversion path offers maximum

pixel capacity, but at the price of higher read noise. The

cross point is set to gain 3×

(approx. 10 dB), where the full

well capacity drops from more than 50 ke- to ~17 ke-. The read noise then drops from

~3.2 e- RMS to

~1.5 e- RMS.

| Gain number |

Gain in dB |

Gain multiply |

Conversion factor |

Read noise RMS |

Full well capacity |

| 0 |

0.0 dB |

1× |

0.76 e-/ADU |

3.52 e- |

50,000 e- |

| 2749 |

9.7 dB |

3× |

0.25 e-/ADU |

3.13 e- |

16,500 e- |

| 2750 |

9.7 dB |

3× |

0.25 e-/ADU |

1.51 e- |

16,500 e- |

| 4030 |

36.0 dB |

63× |

0.012 e-/ADU |

1.28 e- |

800 e- |

Sensor dynamic range, defined as full well capacity

divided by read noise, is greatest when using gain 0,

despite somewhat higher read noise:

At gain = 0, dynamic range is

50,000 / 3.52 = 14,205× At gain = 2750, dynamic range is

16,500 / 1.51 = 10,927×

Also, it is worth noting that in reality the noise floor is

only rarely defined by read noise. Unless the camera is used

with very narrow narrow-band filter (with FWHM only a few nm)

and under very dark sky, the dominant source of noise is the

sky glow. When the noise generated by sky glow exceeds

approximately 4 e- RMS, extremely

low read noise associated with gain set to 2750 or more is not

utilized and dynamic range is unnecessarily limited by the

lowered full well capacity.

So, which gain settings is the best? This depends

on the particular task.

Gain set to 2750 can be utilized if imaging through

narrow-band filter with appropriately short exposures, so

the background noise does not exceed the read noise. This is

typical for aesthetic astro-photography, where the lowered

full well capacity does not negatively influence the result

quality. But even without narrow-band filters, the

extremely low read noise allows stacking of many short

exposures without unacceptable increase of the stacked image

background noise, caused by accumulation of high read noise

of individual exposures. Gain set to 0 offers maximum full well capacity and

the greatest sensor dynamic range, which is appreciated

mainly in research applications. Pass-bands of filters used

for photometry are relatively wide and dominant source of

noise is the sky glow. But also for RGB images, used

for aesthetic astro-photography, higher dynamic range allows

longer exposures while the bright portions of the nebulae

and galaxies still remain under saturation limit and thus

can be properly processed.

Binning

The camera driver and user’s applications offer wide

variety of binning modes up to 4 × 4 pixels as well as all combinations of

asymmetrical binning modes 1 × 2,

1 × 3, 1 × 4, 2 × 4

etc. To allow such flexibility, binning is performed only in

the camera driver (software binning) and does not rely on the

limited capabilities of the hardware binning.

The negative side of software binning is the same download

time like in the case of full-resolution 1 × 1 mode. For typical astronomy usage, the

small fraction of second download time is irrelevant, but for

applications sensitive to download time, the hardware

2 × 2 binning can be useful.

Hardware binning

The C5 camera implements 2 × 2 binning mode in hardware in

addition to normal 1 × 1

binning. This mode can be turned on and off using the

HWBinning parameter in the 'cXusb.ini'

configuration file, located in the same directory like the

'cXusb.dll' driver DLL file itself.

[driver]

HWBinning = true

When the HWBinning parameter is set to

true, the in-camera hardware binning is used and

software binning is no longer available. This mode

brings faster download time, but also introduces several

restrictions:

Maximal binning is limited to 2 × 2, higher binning modes are not

available. Asymmetrical binning modes (1 × 2, 2 × 1, ...) are not allowed.

Adding vs. averaging pixels

The traditional meaning of pixel binning implies adding

of binned pixels. This originated in CCD sensors, where

pixel charges were literally poured together within the

sensor horizontal register and/or the output node.

For CMOS sensors with full 16-bit dynamic resolution,

the negative side of binning is limiting of the sensor

dynamic range, as for instance only 1/4 of maximum charge

in each of the 2 × 2 binned

pixels leads to saturation of resulting pixel. CCDs

eliminated this effect to some extend by increasing of the

charge capacity of the output node and also by decreasing

of the conversion factor in binned modes. But such

possibilities are not available in CMOS detectors.

In theory, the resulting S/N ratio of binned

pixel remains the same regardless if we add or average

them. Let's take for example 2 × 2 binning:

If we add 4 pixels, signal increases 4-times and

noise increases 2-times — three

additive operations increase noise by

√((√2)^2+(√2)^2 ). Resulting S/N

increases 2-times, but only until the sum of all pixels

is lower than the pixel capacity. If we average 4 pixels, signal remains the same

but the noise is lowered to 1/2 as noise is averaged

√((√2)^2+(√2)^2 )/4. Resulting S/N

also increases 2-times, but only until the noise

decreases to lowest possible 1-bit of dynamic

range.

As the C5 camera read noise in the maximum dynamic

range (gain 0) is around 3.5 e-, halving

it in 2 × 2 binning mode

still keeps the read noise above the lower 1-bit limit and

at the same time binned pixel will not saturate. For

higher binning modes, the noise approaches lower limit,

but averaging pixels still protects from pixel saturation,

which is more important than possible S/N limitation

caused by underflow of read noise.

If we take into account that the image background noise

is only rarely defined by the read noise of the sensor, as

the noise caused by background sky glow is typically much

higher, for 16-bit camera averaging pixels is definitely

the better way to bin pixels compared to just adding them.

This is why both software and hardware binning modes in

the C5 cameras are by default implemented as averaging of

pixels, not summing.

However, both software and hardware binning modes can

be switched to sum binned pixels instead of average them

by the BinningSum parameter in the

'cXusb.ini' configuration file:

[driver]

BinningSum = true

Hint: Let’s note there is one more possibility to bin

pixels — in the application

software. This time binning is not performed in camera

hardware nor in the camera driver. Full resolution

1 × 1 image is downloaded

from the camera and software itself then performs binning.

The SIPS software adds pixels instead of averaging them,

but at the same time SIPS converts images from 16-bit to

32-bit dynamic range. This means S/N of the binned images

always increases, pixels never saturate and read noise

never approaches lower limit. The negative side of this

option is two-time bigger images. Binning in photometry

Saturated pixels within bright stars are no issue for

aesthetic astro-photography, but photometry measurement is

invalid if any pixel within the measured object reaches

maximum value, because it is not possible to determine the

amount of lost flux. Software performing photometry (e.g.

the SIPS Photometry tool) should detect saturation value

and invalidate entire photometric point not to introduce

errors.

But binning efficiently obliterates the fact that any

of the binned pixels saturated (with the exception of all

binned pixels reached saturation value). So, using of

binning modes for research applications (photometry and

astrometry) can lead to errors caused by lost flux in

saturated pixels, which cannot be detected by the

processing software due to binning.

This is why the behavior of both software and hardware

binning modes is user-configurable through the

BinningSaturate parameter in the

'cXusb.ini' configuration file:

[driver]

BinningSaturate = true

If the BinningSaturate parameter is set to

true, resulting binned pixel is set to saturation value if

any of the source pixels is saturated. For aesthetic

astro-photography, keeping this parameter false could

result into slightly better representation of bright star

images, but for research applications, this parameter

should always be set to true.

Exposure control

The shortest theoretical exposure time of the C5

cameras depends on the used sensor type:

However, such short exposures have no practical

application, especially in astronomy. The camera firmware

rounds exposure time to a multiply of 100 μs intervals, so in

reality the shortest exposure time of both camera models is

200 μs.

There is no theoretical limit on maximal exposure length,

but in reality, the longest exposures are limited by

saturation of the sensor either by incoming light or by dark

current (see the following chapter about sensor cooling).

Warning: Please note the short exposure timing is properly

handled in the camera firmware version 6.5 and

later. C5A mechanical shutter

C5A cameras are equipped with mechanical shutter, which

is very important feature allowing unattended observations

(fully robotic or just remote setups). Without mechanical

shutter, it is not possible to automatically acquire dark

frames, necessary for proper image calibration etc.

Mechanical shutter in the C5A cameras is designed to be

as reliable as possible, number of open/close cycles is

virtually unlimited, because there are no surfaces rubbing

against each other. The price for high reliability is slow

shutter motion. Luckily, mechanical shuttering is not

necessary for exposure control, only for taking dark

frames and possibly bias frames — all used CMOS sensors are equipped with

electronic shuttering.

Camera firmware optimizes the shutter operation to

avoid unnecessary movements. If a series of light images

is taken immediately one after another, the shutter

remains open not to introduce quite significant delay of

the close/open cycle between each pair of subsequent light

images. In the case next image has to be dark or bias

frame, shutter closes prior to dark frame exposure and

vice versa — shutter remains closed

if a series of dark frames is acquired and opens only

prior to next light frame. If no exposure is taken for

approx. 10 seconds while the

shutter is open (this means after a light image exposure),

camera firmware closes the shutter to cover the sensor

from incoming light.

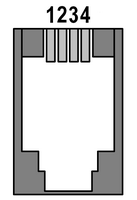

C5S hardware trigger input

The C5S trigger input allows for external hardware to

determine the exact time of exposure start.

The port uses RJ9 (4P4C) four-pin connector. Pins 1 and

2 are connected and have a function of positive pole, pins

3 and 4 are connected to negative pole. The trigger is

activated when an external hardware connects pins 1 and/or

2 with pins 3 and/or 4. The trigger input port is

electrically isolated from the rest of the

camera — power and USB grounds

etc.

|

| 1 |

Positive (+) pin No. 1 |

| 2 |

Positive (+) pin No. 2 |

| 3 |

Negative (-) pin No. 1 |

| 4 |

Negative (-) pin No. 2 |

|

The maximum current, consumed by the short-circuited

trigger port, does not exceed 1 mA.

The trigger input is located on the upper-left portion

of the C5S camera back side, just above the power input

plug.

Back side of the C5S (left) and C5A (right)

cameras GPS exposure timing

C5 cameras can be equipped with GPS receiver module

(see the Optional Accessories chapter). The primary

purpose of the GPS receiver is to provide precise times of

exposures taken with the camera, which is required by

applications dealing with astrometry of fast-moving

objects (fast moving asteroids, satellites, and space

debris on Earth orbit, …).

The GPS module needs to locate at least 5 satellites to

provide exposure timing information. Geographic data are

available if only 3 satellites are visible, but especially

the mean sea level precision suffers if less than 4

satellites are used.

The camera SDK provides functions, allowing users to

access precision exposure times as well as geographics

location. The SIPS software package main imaging camera

control tool window contains the “GPS” tab, which

shows the state of the GPS fix.

Determination of exact exposure time is quite

complicated because of the rolling-shutter nature of the

used sensors. Camera driver does all the calculations

and returns the time of the start of exposure of the

first line of the image. Still, users interested in

precise exposure timing need to include several

corrections into their calculations:

Individual image lines are exposed sequentially.

The time difference between start of exposure of two

subsequent lines is fixed for every sensor type: If the image is binned, single line of resulting

image contains signal from multiple added (or averaged)

lines, each with different exposure time start. The

exposure start of individual lines of the binned images

differs by the single line time difference, multiplied

by the vertical binning factor. If only a sub-frame is read, it must be

considered that the sensor imposes some restrictions to

the sub-frame coordinates. If the required sub-frame

coordinates violate the sensor-imposed rules, camera

driver enlarges the sub-frame region to fully contain

desired sub-frame and then crops it by software. The

provided start exposure time then concerns the first

line actually read from the camera, not the first line

of the resulting (software cropped) image. For

instance, the y-coordinate of the sub-frame must not be

lower than 25 lines. If a sub-frame with lower

y-coordinate is asked by the user, whole frame is read

and cropped by software. Note the camera SDK offers

function AdjustSubFrame, which returns the

smallest sub-frame, fully containing the requested

sub-frame, but also fulfilling the sensor-imposed

sub-frame coordinate restriction. If adjusted sub-frame

is read, no software cropping occurs and image exposure

time concerns the first line of the image. The SIPS

software offers the “Adjust Frame” button, which

adjusts defined sub-frame.

Warning: Please note the precise exposure timing is

properly handled in the camera firmware version 7.10 and

later. Always use the latest camera drivers (ASCOM or Camera

SDK DLLs in Windows, INDI or libraries in Linux) available

on the web. Also, always update the firmware in the

Moravian Camera Ethernet Adapter if the camera is

connected over Ethernet.

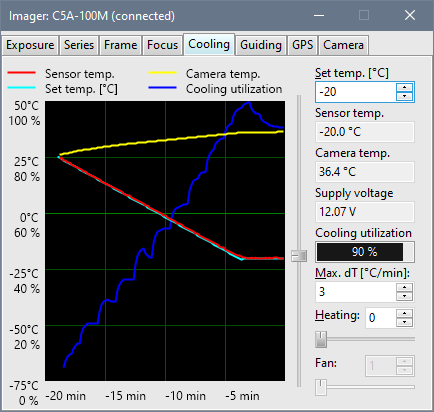

Cooling and power supply

Regulated thermoelectric cooling is capable to cool the CMOS

sensor up to 45 °C below ambient temperature. The Peltier hot side

is cooled by fans. The sensor temperature is regulated with

±0.1 °C precision. High temperature drop and precision regulation

ensure very low dark current for long exposures and allow proper

image calibration.

The airflow is slightly different between C5A and C5S

models.

The C5S (left) and C5A (right) camera vents The cooling performance depends on the environmental conditions

and also on the power supply. If the power supply voltage drops

below 12 V, the maximum temperature

drop is lower.

| Sensor cooling |

Thermoelectric (Peltier modules) |

| Cooling ΔT |

45 °C below ambient regulated |

|

48 °C below ambient maximum |

| Regulation precision |

0.1 °C |

| Hot side cooling |

Forced air flow |

Chip cooling specifications

C5A-100M cameras reaching -45°C below ambient sensor

temperature Overheating protection

The C5 cameras are equipped with an overheating protection

in their firmware. This protection is designed to prevent the

Peltier hot side to reach temperatures above ~50°C sensor

cooling is turned off to stop heat generation by the hot side

of the Peltier TEC modules.

Turning the overheating protection on results in a drop in

cooling power, a decrease in the internal temperature of the

camera and an increase in the temperature of the sensor.

However, when the camera cools its internals down below the

limit, cooling is turned on again. If the environment

temperature is still high, camera internal temperature rises

above the limit an overheating protection becomes active

again.

Power supply

The 12 V DC power supply enables camera operation

from arbitrary power source including batteries, wall adapters

etc. Universal 100-240 V

AC/50-60 Hz, 120 W “brick” adapter is supplied with

the camera. Although the camera power consumption does not

exceed 60 W, the 120 W power supply ensures noise-free

operation.

| Camera power supply |

12 V DC |

| Camera power consumption |

<9 W without cooling |

| |

60 W maximum cooling |

| Power connector |

4-pin plug |

| Adapter input voltage |

100-240 V AC/50-60 Hz |

| Adapter output voltage |

12 V DC/10 A |

| Adapter maximum power |

120 W |

Power supply specification

12 V DC/10 A power supply adapter for C5

camera Mechanical Specifications

Compact and robust camera head measures only 154 × 154 × 76 mm (approx.

6 × 6 × 3 inches).

The head is CNC-machined from high-quality aluminum and black

anodized. The head itself contains USB-B (device) connector and

4-pin 12 V DC power plug, no other parts, except a

“brick” power supply, are necessary. Another connector on

the camera head allows control of optional external filter

wheel.

Integrated mechanical shutter of the C5A models allows

automatic dark frame exposures, which are necessary for

unattended, robotic setups.

| Internal mechanical shutter |

C5A yes, blade shutter |

| |

C5S no |

| Camera head dimensions |

154 mm × 154 mm × 76 mm |

| Camera head weight |

1.9 kg

(without filter wheel) |

| |

2.8 kg

(with the “XL” external filter wheel) |

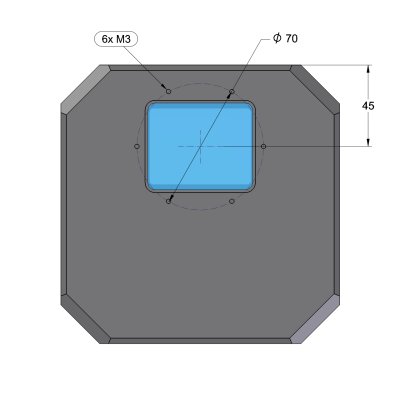

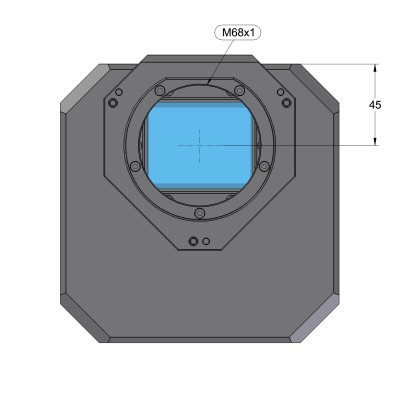

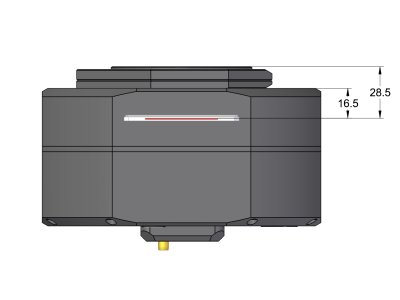

Mechanical specification C5A camera head front view

C5A camera head interface for filter wheel or

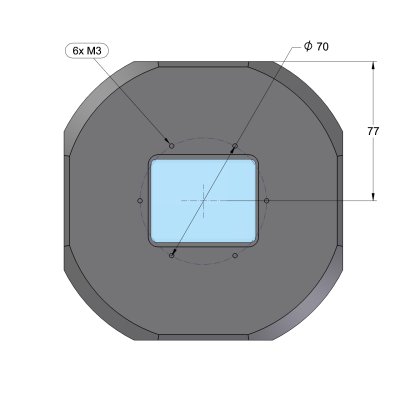

tiltable adapter base Filter wheels or tiltable adapter base are attached to the

camera head using six M3 screws around the 70 mm diameter ring.

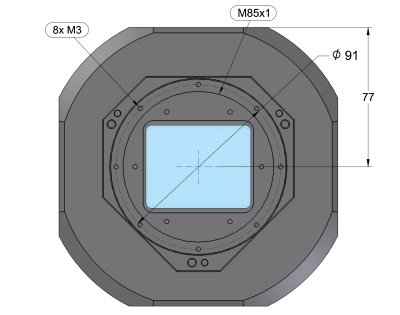

C5A camera with M85 × 1

threaded adapter

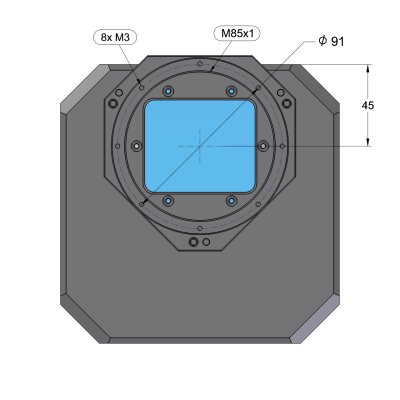

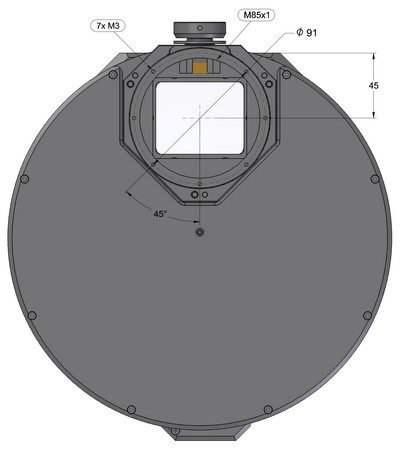

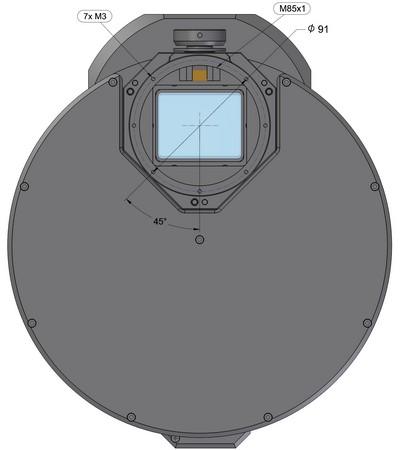

C5A camera head with M85 × 1 adapter front view

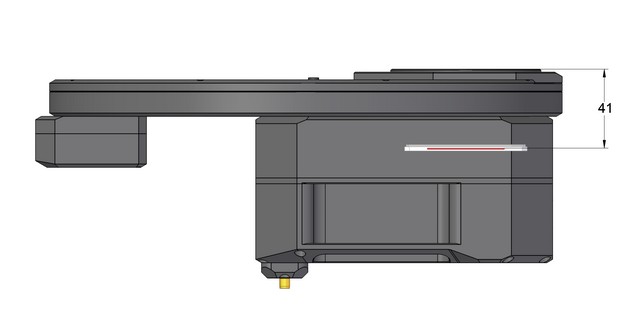

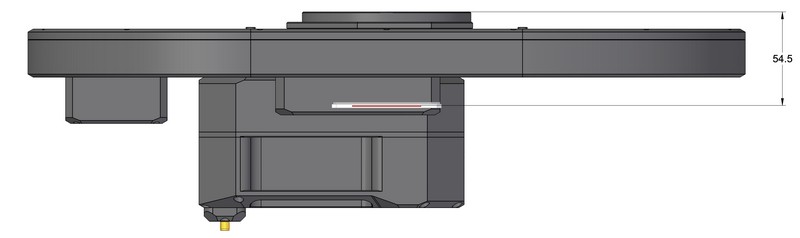

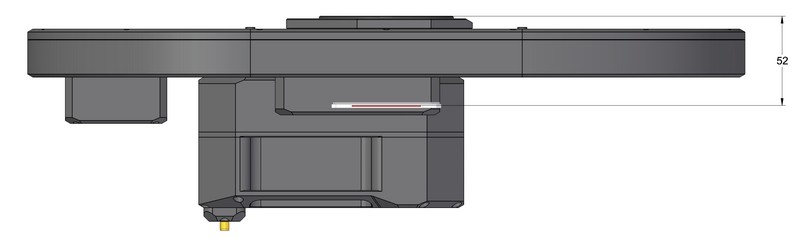

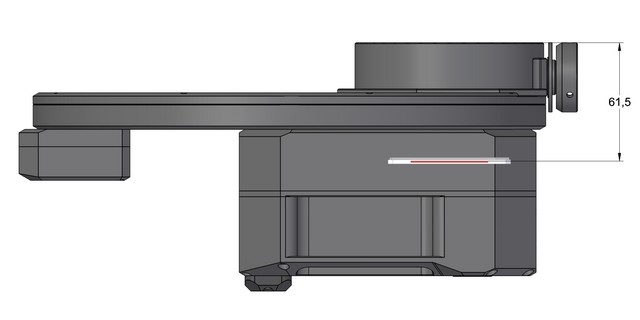

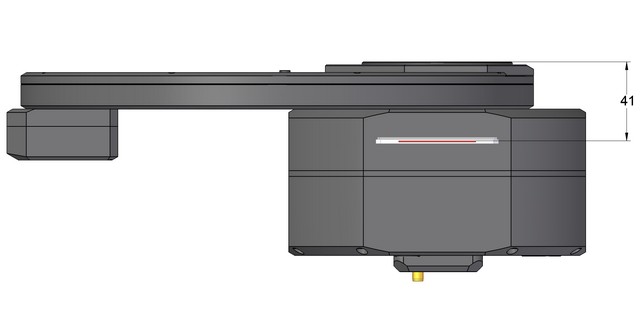

C5A camera head with M85 × 1 adapter side view with back focal

distance

C5A camera with External Filter wheel with

M85 × 1 adapter Back Focal

Distance The stated back focal distances (BFD) include corrections

for all optical elements in the light path (cold chamber

optical window, sensor cover glass, ...), fixed in the camera

body. So, stated values are not mechanical, but optical back

focal distances. However, no corrections for filters are

included, as the thicknesses of various filters are very

different.

Hint: Note the M85 × 1 adapter

is also equipped with eight M3 threaded holes arranged around

the 91 mm diameter circle. These

threaded holes provide alternative mean of camera attachment

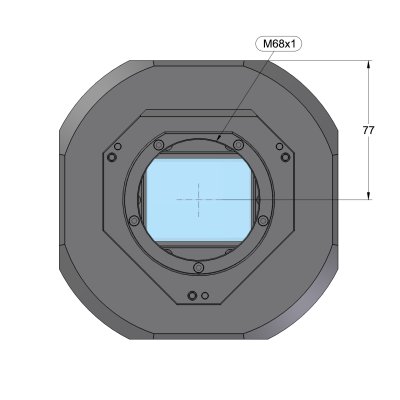

to the optical system. C5A camera with M68 × 1

threaded adapter

There are two variants of the M68 × 1 adapter available. The

version 1 consists of two parts (the base and the M68 threaded

ring attached with 5 screws) and thus its total height is

greater. The newer M68 × 1 adapter version 2 is

machined from one piece and its total height is smaller, which

results into shorter total BFD.

C5A camera head with M68 × 1 adapter front view

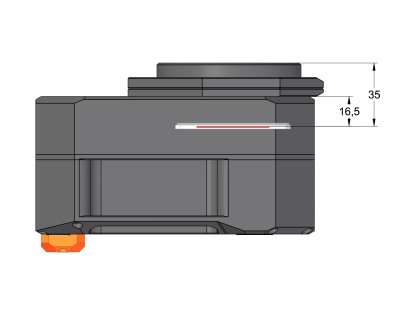

C5A camera head with M68 × 1 v1 adapter Back Focal

Distance

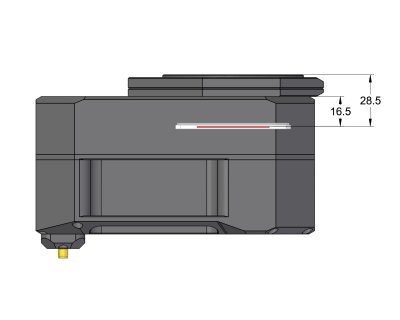

C5A camera head with M68 × 1 v2 adapter Back Focal

Distance

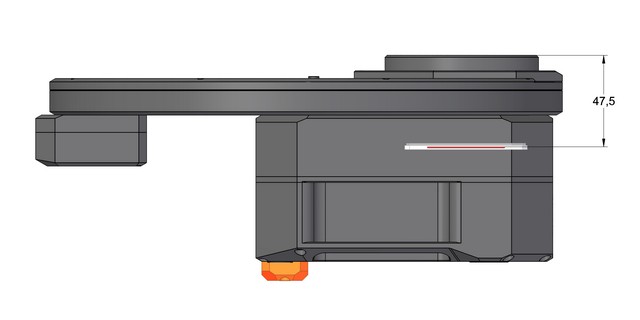

C5A camera with External Filter wheel with

M68 × 1 v1 Back Focal

Distance

C5A camera with External Filter wheel with

M68 × 1 v2 Back Focal

Distance C5A camera with Standalone Filter Wheel

While all EFWs from “XS” to “L” size are

designed to preserve the very same BFD on all Cx cameras, the

SFW naturally increased the BFD because of the design using

two overlapping wheels. The resulting BFD depends on the

adapter used.

C5A camera with Standalone Filter wheel with

M85 × 1 adapter Back Focal

Distance

C5A camera with Standalone Filter wheel with

M68 × 1 version 2

adapter C5A camera with C5-OAG with M85 × 1 thread

C5-OAG is designed to be used with the XL-sized External

filter wheels only.

C5A camera with External Filter wheel with

C5-OAG

C5A camera with External Filter wheel with C5-OAG

Back Focal Distance C5S camera head front view

C5S camera head interface for filter wheel or

tiltable adapter base Filter wheels or tiltable adapter base are attached to the

camera head using six M3 screws around the 70 mm diameter ring.

C5S camera with M85 × 1

threaded adapter

C5S camera head with M85 × 1 adapter front view

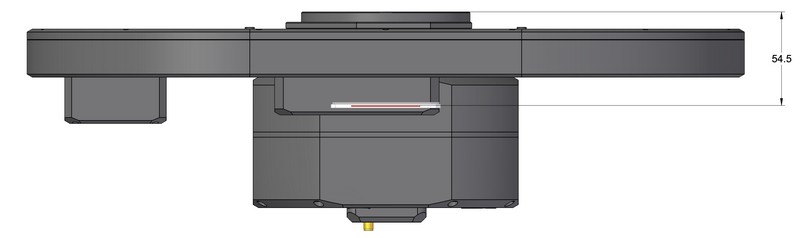

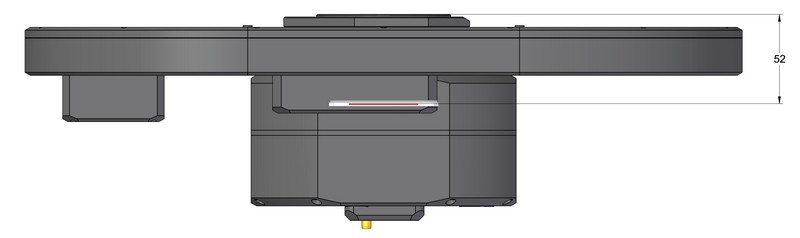

C5S camera head with M85 × 1 adapter side view with back focal

distance

C5S camera with External Filter wheel with

M85 × 1 adapter Back Focal

Distance The stated back focal distances (BFD) include corrections

for all optical elements in the light path (cold chamber

optical window, sensor cover glass, ...), fixed in the camera

body. So, stated values are not mechanical, but optical back

focal distances. However, no corrections for filters are

included, as the thicknesses of various filters are very

different.

Hint: Note the M85 × 1 adapter

is also equipped with eight M3 threaded holes arranged around

the 91 mm diameter circle. These

threaded holes provide alternative mean of camera attachment

to the optical system. C5S camera with M68 × 1

threaded adapter

There are two variants of the M68 × 1 adapter available. The

version 1 consists of two parts (the base and the M68 threaded

ring attached with 5 screws) and thus its total height is

greater. The newer M68 × 1 adapter version 2 is

machined from one piece and its total height is smaller, which

results into shorter total BFD.

C5S camera head with M68 × 1 adapter front view

C5S camera head with M68 × 1 v1 adapter side view with back focal

distance

C5S camera head with M68 × 1 v2 adapter side view with back focal

distance

C5S camera with External Filter wheel with

M68 × 1 v1 adapter Back Focal

Distance

C5S camera with External Filter wheel with

M68 × 1 v2 adapter Back Focal

Distance C5S camera with Standalone Filter Wheel

While all EFWs from “XS” to “L” size are

designed to preserve the very same BFD on all Cx cameras, the

SFW naturally increased the BFD because of the design using

two overlapping wheels. The resulting BFD depends on the

adapter used.

C5S camera with Standalone Filter wheel with

M85 × 1 adapter Back Focal

Distance

C5S camera with Standalone Filter wheel with

M68 × 1 version 2

adapter C5S camera with C5-OAG with M85 × 1 thread

C5-OAG is designed to be used with the XL-sized External

filter wheels only.

C5S camera with External Filter wheel with

C5-OAG

C5S camera with External Filter wheel with C5-OAG

Back Focal Distance Filter distance to sensor

It is necessary to know the distance of the filter entrance

aperture from the sensor to calculate possible vignetting

(partial shielding of the sensor edge parts from the incoming

lights). In the case of C5 cameras, this is technically not an

“aperture”, as the filters are squares. So, instead of

comparing filter aperture diameter to sensor diagonal, filter

hole linear dimension must be compared to the longer side of

the sensor.

Distance of the filter wheel entrance pupil from

the sensor The 7-positions filter wheel for 50 × 50 mm filters entrance dimension is

48 mm, 5-positions filter wheel

for 65 × 65 mm filters entrance

dimension is 63 mm. The C5A-100M

sensor longer side measures 43.86 mm, while the C5A-150M sensor longer side

measures 53.42 mm.

Optional accessories

Various accessories are offered with C5 cameras to enhance

functionality and help camera integration into imaging setups.

External filter wheels

The C5 camera contains electronics and an 8-pin connector

on the camera head to control filter wheels. As the mechanical

interface of the C5 cameras, intended to attach filter wheels,

differs from the interface on the C3 or C4 cameras (see the

chapter Camera head front view of the Mechanical Specification

section for details), C5 cameras are not compatible with the

“M” or “L” external filter wheels intended for

C3 or C4 lines. New “XL” size external filter wheel is

designed especially for the C5 series.

C5 camera with the “XL” filter wheel

attached The ”XL” filter wheel housing can accommodate two

filter wheels:

Standalone filter wheels

The external filter wheel diameter has construction limits,

it is not possible to simply increase both EFW shell and

filter wheel itself. The diameter and weight would be so big,

that usage of such wheels would not be practical.

Natural solution of this problem is placing of two smaller

filter wheels beside each other. The total number of filter

positions is lower than the sum of positions in both wheels

from obvious reasons: one position in each wheel must remain

empty (clear) and it is set as an actual position when a

filter from the other wheel is to be used not to interfere

with it. So, if for instance two filter wheels with five

positions each are used, we denote such wheel as

“8+Clear” positions. This means four positions in both

wheels may be used for any filter, which makes 8 total filter

positions. When both filter wheels are set to index 0 (the

clear position), one additional clear position is added to the

total number of filter positions.

The SFW-5XL on the C5S camera The Standalone Filter Wheel (SFW), compatible with

C5 cameras, comes in the “XL” flavor, which indicates

it is even greater than the larges “L” sized EFW

available. Number of available positions depends on filter

size:

8+Clear positions for 65 × 65 mm square filters, suitable for C5

cameras (both asymmetrical C5A and symmetrical C5S

variants) 12+Clear positions for 50 × 50 mm square filters, suitable for

C5-100M cameras (with some vignetting over the sensor short

edge)

The SFW filter wheels are equipped with 12 V DC

5.5/2.5 mm power plug as

well as USB 1.1 data connection. Latest SIPS v4.1 and later

software contains native driver for these wheels, as well as

Moravian Camera Ethernet Adapter firmware, ASCOM drivers for

windows, Linux libraries and INDI/INDIGO drivers are available

etc. Also, the Moravian Camera SDK contains libraries, headers

and API description allowing to control the SFW from other

software packages as well as from Python etc.

Telescope adapters

There are basically only two types of telescope

adapters, available for C5 cameras:

M85 × 1 threaded

adapter, intended for both C5A-100M and C5A-150M camera

models. This adapter is also equipped with eight M3 threaded

holes arranged around the 91 mm

diameter circle, providing alternative possibility to attach

the C5 camera to the optical system. M68 × 1 threaded

adapter, suitable for C5A-100M camera only due to limited

aperture, possibly causing vignetting of the large sensor of

C5A-150M camera.

Both adapters have adjustable tilt and both can be mounted

either on the adapter base on the camera head or on the

External filter wheel front plane.

Off-Axis Guider adapter

C5 camera can be optionally equipped with Off-Axis Guider

Adapter. This adapter contains flat mirror, tilted by 45° to

the optical axis. This mirror reflects part of the incoming

light into guider camera port. The mirror is located far

enough from the optical axis not to block light coming to the

main camera sensor, so the optics must be capable to create

large enough field of view to illuminate the tilted

mirror.

Position of the OAG reflection mirror relative to

optical axis The C5-OAG offers the M85 × 1

thread on the telescope side. The back focal distance is

61.5 mm.

The C5-OAG is designed for cameras using the XL-size

external filter wheel. The guiding camera will not be able to

reach focus is the OAG is mounted directly to the camera

head.

C5-OAG adapter (left), OAG on then C5 camera with

External filter wheel (right) OAG guider port is compatible with C0 and C1 cameras when

mounted on the C5A camera. Mechanical constrains of the C5S

camera head allows usage of only smaller C0 models. It is

necessary to replace the CS/1.25” adapter

with short, 10 mm variant.

Because C1 cameras follow CS-mount standard, (BFD

12.5 mm), any

camera following this standard with 10 mm long 1.25” adapter

should work properly with the C5-OAG.

GPS receiver module

The C5 cameras can be equipped with an optional GPS

receiver module, which allows very precise timing of the

exposure times. Geographic location data are also available to

the control software through specific commands.

The used GPS receiver is compatible with GPS, GLONASS,

Galileo and BeiDou satellites.

The GPS receiver can be attached to the back side of the

camera head. If the GPS module is removed, the GPS port is

covered with a flat black cover.

The C5A (left) and C5A (right) cameras with GPS

receiver module with external antenna Spare desiccant containers

The C3 cameras are supplied with silicagel container,

intended to dry the sensor cold chamber. This container can be

unscrewed and desiccant inside can be dried in the oven (see

the camera User's Manual).

The whole desiccant container can be baked to dry

the silica-gel inside or its content can be poured out after

unscrewing the perforated internal cap and baked

separately Container shipped with the camera by default does not

exceed the camera head outline. It is equipped with a slot for

tool (or for just a coin), allowing releasing and also

tightening of the container. Containers intended for enhanced

cooling cameras are prolonged as the camera thickness is

greater in the case of this variant.

It is possible to order spare container, which makes

desiccant replacement easier and faster. It is possible to dry

the spare container with silicagel and then only to replace it

on the camera. Spare container is supplied including the

air-tight cap.

Spare container can be supplied also in a variant that

allows manipulation without tools. But this container is

longer and exceeds camera outline. If the space behind the

camera is not critical, this container can make desiccant

exchange even easier.

Optional cap, standard and tool-less container

variants Moravian Camera Ethernet Adapter

The Moravian Camera Ethernet Adapter allows connection of

up to 4 Cx cameras of any type on the one side and 1 Gbps

Ethernet on the other side. This adapter allows access to

connected Cx cameras using routable TCP/IP protocol over

practically unlimited distance.

The Moravian Camera Ethernet Adapter device (left)

and adapter with two connected cameras (right) Moravian Camera Ethernet Adapter devices are described in

detail here.

Software Support

Always use the latest versions of the system driver package for

both Windows and Linux system. Older versions of drivers may not

support new camera models (like C0) or latest versions or existing

series (like C1 version 3).

If the camera is controlled through the Moravian Camera

Ethernet Adapter, make sure the device firmware is updated to

the latest version available.

Also, always use the latest version of the SIPS software

package, older versions may not support latest cameras correctly.

If a driver for 3rd party software package is used

(e.g. ASCOM or INDI drivers), always update the driver to the

latest available version.

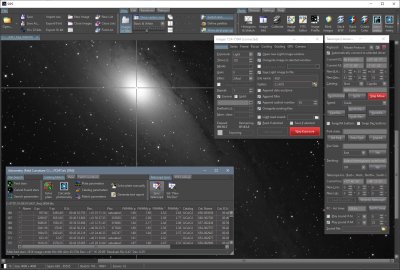

SIPS

Powerful SIPS (Scientific Image Processing System)

software, supplied with the camera, allows complete camera

control (exposures, cooling, filter selection etc.). Also

automatic sequences of images with different filters,

different binning etc. are supported. With full ASCOM standard

support, SIPS can be also used to control other observatory

equipment. Specifically the telescope mounts, but also other

devices (focusers, dome or roof controllers, GPS receivers

etc.).

SIPS also supports automatic guiding, including image

dithering. Both “autoguider” port hardware interface

(6-wire cable) and mount “Pulse-Guide API” guiding

methods are supported. For hi-quality mounts, capable to track

without the necessity to guide at least during one exposure,

inter-image guiding using the main camera only is

available.

SIPS controlling whole observatory (shown in

optional dark skin) But SIPS is capable to do much more than just camera and

observatory control. Many tools for image calibration, 16 and

32 bit FITS file handling, image

set processing (e.g. median combine), image transformation,

image export etc. are available.

SIPS handles FITS files, supports image calibration

and processing As the first “S” in the abbreviation SIPS means

Scientific, the software supports astrometric image reduction

as well as photometric processing of image series.

SIPS focuses to advanced astrometric and

photometric image reduction, but also provides some very

basic astro-photography processing SIPS software package is freely available for download from this www site. All functions

are thoroughly described in the SIPS User's Manual, installed

with every copy of the software.

Automatic guiding

SIPS software package allows automatic guiding of the

astronomical telescope mounts using separate guiding

camera. Proper and reliable automatic guiding utilizing

the computational power of Personal Computer (e.g.

calculation of star centroid allows guiding with sub-pixel

precision) is not simple task. Guiding complexity

corresponds to number of parameters, which must be entered

(or automatically measured).

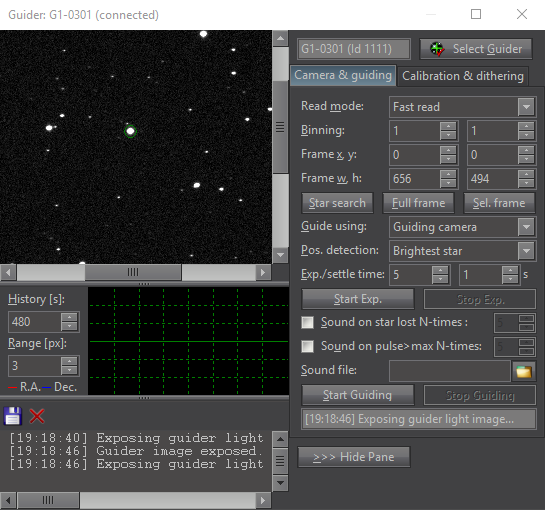

The SIPS “Guider” tool window The “Guiding” tool allows switching of

autoguiding on and off, starting of the automatic

calibration procedure and recalculation of autoguiding

parameters when the telescope changes declination without

the necessity of new calibration. Also swapping of the

German Equatorial mount no longer requires new autoguider

calibration. There is also a graph showing time history of

guide star offsets from reference position in both axes.

The length of graph history as well as the graph range can

be freely defined, so the graph can be adjusted according

to particular mount errors and periodic error period

length. Complete log of calibration procedure, detected

offsets, correction pulses etc. is also shown in this

tool. The log can by anytime saved to log file.

An alternative to classic autoguiding is the

inter-image guiding, designed for modern mounts, which are

precise enough to keep tracking with sub-pixel precision

through the single exposure, and irregularities only

appear on the multiple-exposure time-span. Inter-image

guiding then performs slight mount position fixes between

individual exposures of the main camera, which eliminates

“traveling” of the observed objects through the

detector area during observing session. This guiding

method uses main imaging camera, it does not use another

guiding camera and naturally does not need neither OAG nor

separate guiding telescope to feed the light into it.

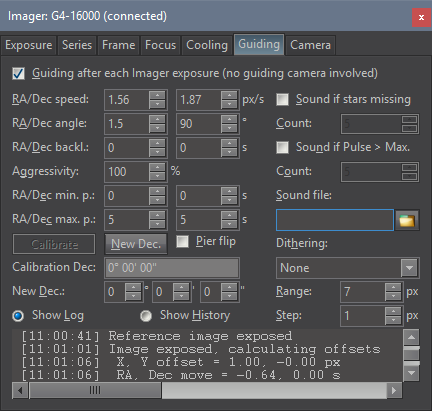

Inter-image guiding controls in the

Guiding tab of the Imager Camera tool

window Advanced reconstruction of color information of

single-shot-color cameras

Color sensors have red, green and blue filters applied

directly on individual pixels (so-called Bayer mask).

Every pixel registers light of particular color only

(red, green or blue). But color image should contain all

three colors for every pixel. So it is necessary to

calculate missing information from values of neighboring

pixels.

There are many ways how to calculate missing color

values — from simple extending of

colors to neighboring pixels (this method leads to coarse

images with visible color errors) to methods based on

bi-linear or bi-cubic interpolation to even more advanced

multi-pass methods etc.

Bi-linear interpolation provides significantly better

results than simple extending of color information to

neighboring pixels and still it is fast enough. But if the

telescope/lens resolution is close to the size of

individual pixels, color artifacts appear close to fine

details, as demonstrated by the image below left.

The above raw image with colors calculated

using bi-linear interpolation (left) and the same raw

image, but now processed by the multi-pass de-mosaic

algorithm (right) Multi-pass algorithm is significantly slower compared

to single-pass bi-linear interpolation, but the resulting

image is much better, especially in fine details. This

method allows using of color camera resolution to its

limits.

SIPS offers choosing of color image interpolation

method in both “Image Transform” and “New Image

Transform” tools. For fast image previews or if the

smallest details are significantly bigger than is the

pixel size (be it due to seeing or resolution of the used

telescope/lens) the fast bi-linear interpolation is good

enough. But the best results can be achieved using

multi-pass method.

Shipping and Packaging

C5 cameras are supplied in the foam-filled, hard

carrying case containing:

Camera body with a user-chosen telescope

adapter. A 100-240 V AC input, 12 V DC output

“brick” adapter with 1 m

long power cable. 2 m long USB 3.0 A-B cable

for connecting camera to host PC. USB Flash Drive with camera drivers, SIPS software

package with electronic documentation and PDF version of

User's Manual. A printed copy of camera User's Manual

Image Gallery

Example images captured with C5 cameras.

|

| Object |

LDN43 “Batman” nebula |

| Author |

CielAustral group |

| Camera |

C5A-100M |

| Filters |

LRGB |

| Exposure |

42 hours, 45 minutes |

| Telescope |

PlaneWave CDK610 |

|

|

| Object |

NGC1512 galaxy |

| Author |

CielAustral group |

| Camera |

C5A-100M |

| Filters |

LRGB |

| Exposure |

44 hours, 45 minutes |

| Telescope |

PlaneWave CDK610 |

|

|

| Object |

WR8 (Wolf–Rayet star) |

| Author |

CielAustral group |

| Camera |

C5A-100M |

| Filters |

RGB + Hα + OIII |

| Exposure |

110 hours, 55 minutes |

| Telescope |

PlaneWave CDK610 |

|

|

| Object |

NGC3469 galaxy |

| Author |

CielAustral group |

| Camera |

C5A-100M |

| Filters |

LRGB + Hα |

| Exposure |

72 hours, 50 minutes |

| Telescope |

PlaneWave CDK610 |

|

|

| Object |

NGC2626 nebula |

| Author |

CielAustral group |

| Camera |

C5A-100M |

| Filters |

LRGB + Hα |

| Exposure |

62 hours, 50 minutes |

| Telescope |

PlaneWave CDK610 |

|

|

| Object |

NGC3521 galaxy |

| Author |

CielAustral group |

| Camera |

C5A-100M |

| Filters |

LRGB + Hα |

| Exposure |

62 hours, 20 minutes |

| Telescope |

PlaneWave CDK610 |

|

|

| Object |

M88 galaxy |

| Author |

CielAustral group |

| Camera |

C5A-100M |

| Filters |

LRGB + Hα |

| Exposure |

45 hours, 15 minutes |

| Telescope |

PlaneWave CDK610 |

|

|

| Object |

M1 “Crab” nebula |

| Author |

Wolfgang Promper |

| Camera |

C5A-150M |

| Filters |

Bessel B (as blue), Bessel V (as green), and

Sloan r' (as red) |

| Exposure |

1.5 hour luminance and 30 min each color

channel |

| Telescope |

1.5 m ASA |

|

|

| Object |

NGC1398 galaxy |

| Author |

Wolfgang Promper |

| Camera |

C5A-150M |

| Filters |

Bessel B (as blue), Bessel V (as green), and

Sloan r' (as red) |

| Exposure |

1.5 hour luminance and 30 min each color

channel |

| Telescope |

1.5 m ASA |

|

|

| Object |

Detailed core of the M42 nebula |

| Author |

Wolfgang Promper |

| Camera |

C5A-150M |

| Filters |

Bessel B (as blue), Bessel V (as green), and

Sloan r' (as red) |

| Exposure |

3 min 20'sec each

color channel |

| Telescope |

1.5 m ASA |

|

|

| Object |

NGC253 galaxy core |

| Author |

Wolfgang Promper |

| Camera |

C5A-150M |

| Filters |

Sloan g' (as blue), r' (as green), and i' (as

red) |

| Exposure |

20, 20, 20 min |

| Telescope |

1.5 m ASA |

|

|

| Object |

“Hour Glass” nebula |

| Author |

Wolfgang Promper |

| Camera |

C5A-150M |

| Filters |

Sloan g' (as blue), r' (as green), and i' (as

red) |

| Exposure |

20, 20, 20 min |

| Telescope |

1.5 m ASA |

|

|

| Object |

M16 “Eagle” nebula |

| Author |

Wolfgang Promper |

| Camera |

C5A-150M |

| Filters |

Sloan g' (as blue), r' (as green), and i' (as

red) |

| Exposure |

20, 20, 20 min |

| Telescope |

1.5 m ASA |

|

|

| Object |

Omega Centauri |

| Author |

Mark McComiskey |

| Camera |

C5A-100M |

| Filters |

LRGB |

| Exposure |

11 hours,

17 min |

| Telescope |

ASA 600 |

|

|

| Object |

NGC4753 |

| Author |

Mark McComiskey |

| Camera |

C5A-100M |

| Filters |

LRGB |

| Exposure |

21 hours,

40 min |

| Telescope |

ASA 600 |

|

|

| Object |

NGC5128 “Centaurus A” galaxy |

| Author |

Wolfgang Promper |

| Camera |

C5A-150M |

| Filters |

Sloan g' (as blue), r' (as green), and i' (as

red) |

| Exposure |

20, 20, 20 min |

| Telescope |

1.5 m ASA |

|

|

| Object |

M42 “Orion” nebula |

| Author |

Bill Long |

| Camera |

C5A-150M |

| Filters |

L, R, G, B |

| Exposure |

448, 100, 106, 102 min |

| Telescope |

PlaneWave CDK14 |

|

|

| Object |

M7 star cluster |

| Author |

Patrick Winkler |

| Camera |

C5A-150M |

| Filters |

L, R, G, B |

| Exposure |

66, 40, 40, 40 min |

| Telescope |

ASA H400, 400 mm

f/2.4 |

|

|

| Object |

M42 “Orion” nebula |

| Author |

Patrick Winkler |

| Camera |

C5A-150M |

| Filters |

R, G, B |

| Exposure |

45 min (15 min per color) |

| Telescope |

ASA H400, 400 mm

f/2.4 |

|

|

| Object |

NGC3372 “Carina” nebula |

| Author |

Patrick Winkler |

| Camera |

C5A-150M |

| Filters |

R, G, B |

| Exposure |

45 min (15 min per color) |

| Telescope |

ASA H400, 400 mm

f/2.4 |

|

|